CALIBRATION OF PRODUCT IN STORAGE TANK

Calibration is the technique of calculating product, using standard quantified dimensions (like height, length, breath, diameter, in millimeters), to align with graded volume precision of the storage tank.

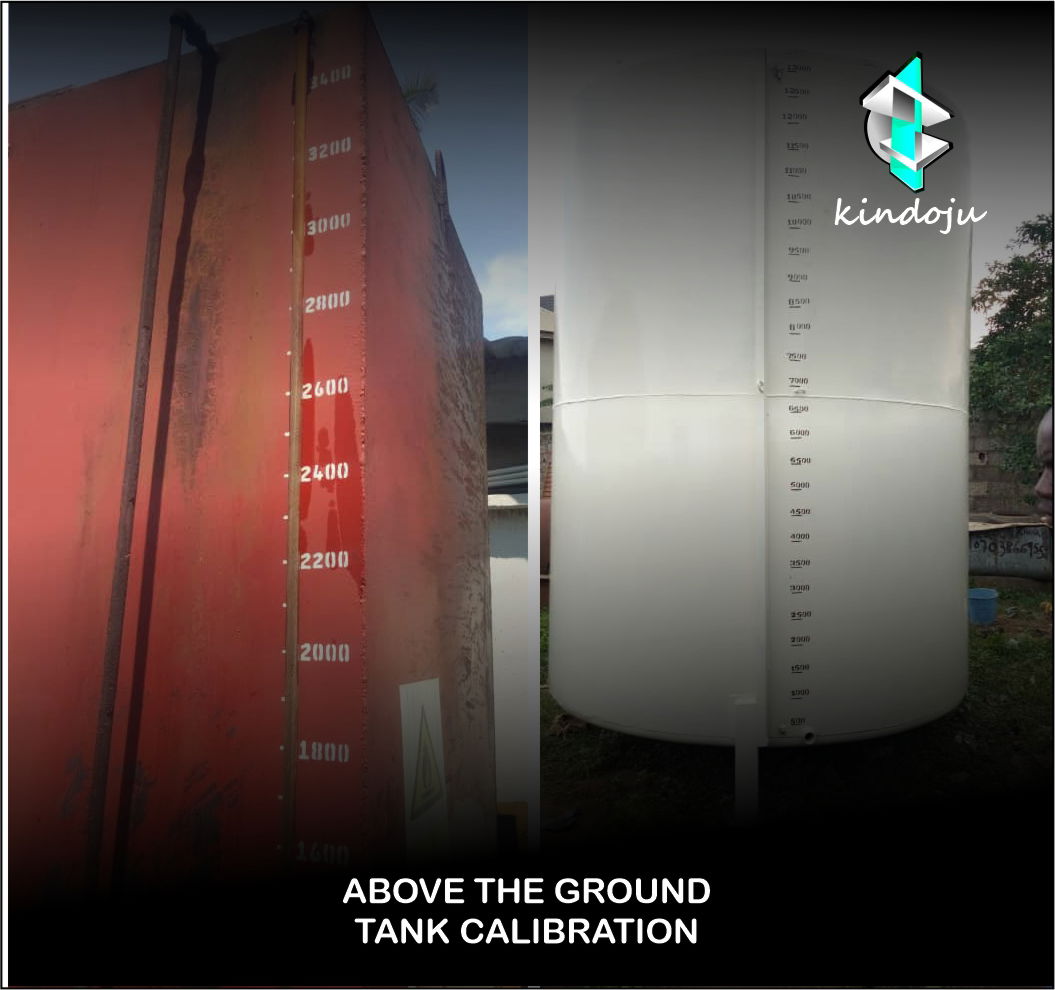

After each calibration, a volumetric table containing liquid volume levels (in millimeters) tabulated against the actual liquid volume (in liters) of the storage tank is generated for the client’s use.

Being assertive is “gold” as it pertains to calibration. As knowing the accurate volume (measurement) of product in the storage tanks, at every point in time, aids accountability (business gain/loss) of product, and also boosts the integrity of the filling station owners / managers, before petroleum governing bodies, petroleum tanker drivers and clients.

Various elements (Theft, product leakage; expansion or compression of storage tank over time) affect the consistency of the measured product in the tank. This creates the need to calibrate storage tank after:

I. Cleaning (as the sludge / dirt removed would reduce the product’s volume) the tank.

II. Product leakage detection.

III. Installation of new or re-commissioned storage tank.

IV. Every five (5) years

Calibration is done either:

1. Wet (with a liquid in the storage tank): is adopted for irregular storage tanks or when the tank dimensions cannot be ascertained (like underground storage tanks). Here the volume of the tank is determined at incremental elevations, as a known quantity of liquid is transferred from a container, to the tank at intervals.

2. Dry / geometric

I. Without a liquid in the storage tank: is adopted for regular storage tanks (horizontal or vertical) with definite dimensions. Here the dimension (the thickness, length, height, radius, diameter and circumference) as it pertains to the tank is taken to determine its volume.

II. 3D Lazer scanning: here, the presence of a liquid is irrelevant. It calibrates using targets (light detection and ranging) to scan a tank from multiple (millions of individual points,) locations and register them with high accuracy. This gives it, the ability to create a mathematical model of the storage tank. Its built-in camera can be used to capture digital images of the tank and its content. The algorithms used include the inclination, inner and external dimensions of the tank. This method allows for practical safety; minimal fuel station downtime; high accuracy. However it is very expensive.