PRESSURE TESTING

Profitability is anchored on creating an excellent customer experience. At filling stations, the more efficient the fuel pump dispenses, the more satisfied customers are.

We at KINDOJU are certified by the Department of Petroleum Resources (DPR), to pressure test new and existing tanks and pipelines, using the state of art equipment, to achieve the best achievable result.

In the oil and gas sector, Pressure testing is done to check for leakages in storage (underground and surface) tanks and pipelines. It is also advisable to pressure test, whenever a storage tank is cleaned or the pipelines are maintained.

Equipment used for pressure testing includes:

- Compressor, which is filled with either oxygen or Nitrogen gas:

- Nitrogen is mostly used in comparison to oxygen, because it is not easily combustible. It’s also used to know the capacity of the tank.

- Oxygen is used to test new tanks and pipeline. It’s also used for old tanks that are being re-commissioned. It’s cheaper than nitrogen.

- Water is mostly used if the storage tank is a surface one. Dye is added to the water, so that the leakage can be easily detected.

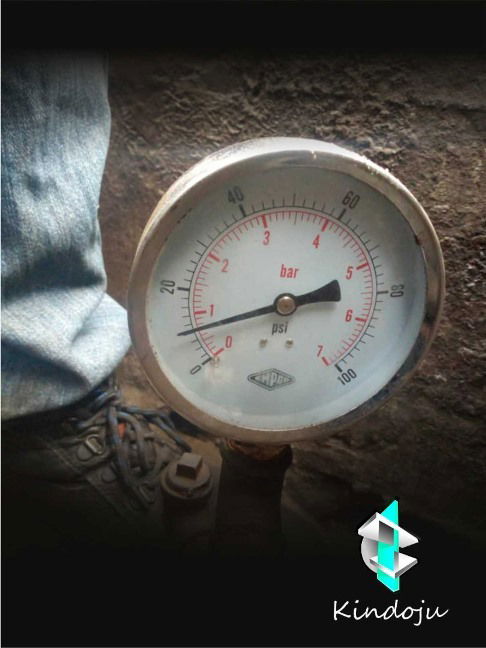

- Pressure gauge is used to measure the intensity of the water or gas (oxygen/nitrogen), introduced into the storage tank and pipeline. We introduce the use of dial pressure gauges, of a minimum of 100mm in diameter, with a pre-calibrated pressure relief valve.

- Pressure relief valve is pre-calibrated. It is used to prevent the pressure in the tank and pipelines from going beyond the set value or the acceptable range.

Before initiating a pressure test, it is mandatory to obtain an approval from the governing authorities (like the DPR, for those in Nigeria). Afterwards, all safety precautions (including restricting the work environment from pedestrians) must be adhered.

The Procedures undertaken in pressure testing an underground storage tank (UST), includes:

- Loosening the tank head to replace the flange/gasket, if it is worn out. The tank head is then replaced and the bolts are securely tightened.

- Loosening and retightening all fittings. In some cases, only the union is removed and re-plugged.

- Connecting the pressure gauge to one of the sockets on the tank head, and tightened.

- Connecting the compressor to the pressure gauge. Then fill the pipelines and UST with nitrogen. When the desired pressure level is reached, the compressor is turned off. The whole system is then left for a while (ideally approximately 4 hours for pipelines and between 8 – 24 hours for tanks). After this, if the pressure level of the gauge reduces from the desired pressure, then it’s an indication that, there is leakage.

Fixing leakages detected in the UST and pipelines. The following solutions below can be adopted.

- The tank will be put out of use/condemned.

- The fiberglass technology can be applied to restore tank.

- For pipelines, the fittings are loosed and retightened firmly.

After a successful pressure test operation, the vendor issues the client a certificate/report.